The Role of Aluminum Forging in Motorcycle Components #

Aluminum forging has become a cornerstone in the production of high-performance motorcycle parts. Leveraging the unique properties of aluminum, such as its high strength-to-weight ratio and natural resistance to corrosion, forged components offer significant advantages over traditional manufacturing methods. These benefits translate into lighter, stronger, and more durable motorcycle parts, directly impacting the overall performance and longevity of motorcycles.

Key Benefits of Aluminum Forged Motorcycle Parts #

- Enhanced Strength: Forged aluminum parts exhibit superior mechanical properties, making them more resilient under stress and load.

- Reduced Weight: The lightweight nature of aluminum contributes to improved fuel efficiency and handling.

- Corrosion Resistance: Aluminum’s natural resistance to corrosion ensures longer-lasting components, even in challenging environments.

- Improved Performance: The combination of strength and reduced weight leads to better acceleration, braking, and maneuverability.

Typical Applications in Motorcycles #

Aluminum forging is utilized in a variety of motorcycle components, including:

- Engine parts

- Suspension elements

- Frame components

These applications benefit from the material’s ability to withstand high stress while maintaining a low overall weight.

Manufacturing Expertise: Al Forge Tech #

Al Forge Tech specializes in the production of forged aluminum motorcycle parts, offering a range of manufacturing processes tailored to client needs. Techniques such as cold forging and open die forging are employed to ensure high-quality, durable components. The company welcomes inquiries for OEM services, supporting clients in developing custom solutions for their specific requirements.

Product Gallery: Aluminum Forged Motorcycle Parts #

Manufacturing Processes Offered #

These processes are selected based on the specific requirements of each component, ensuring optimal performance and reliability.

Contact Information #

For further details or to discuss custom requirements, please reach out via:

- Address: No.266, Nanxiang Rd., Nantou City, Nantou County 540, Taiwan (R.O.C.)

- TEL: +886-49-2227-058

- FAX: +886-49-2227-028

- E-mail: aft@aft-forge.com.tw, alforgetech@gmail.com

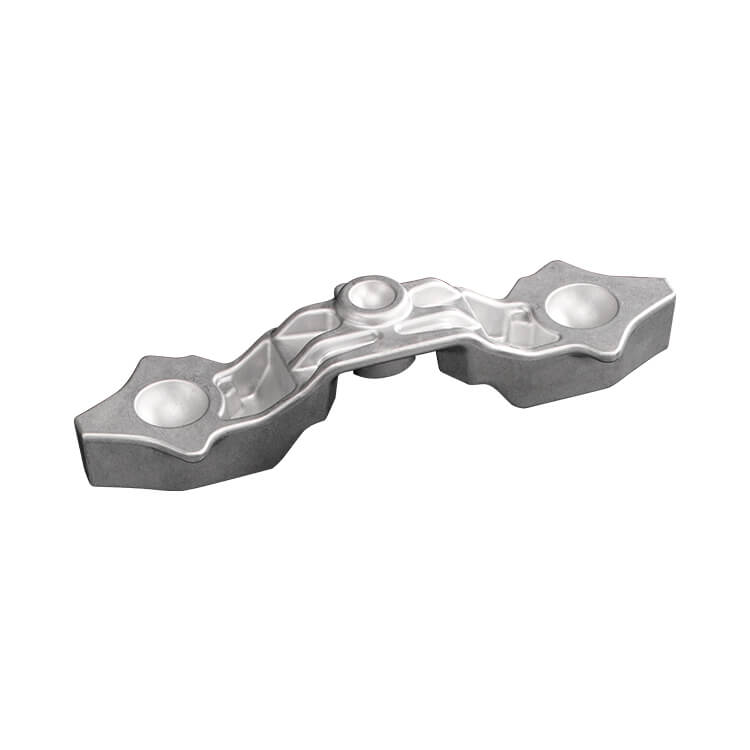

Triple Clamp

Triple Clamp Triple Clamp

Triple Clamp Triple Clamp

Triple Clamp Triple Clamp

Triple Clamp Transmission Casing

Transmission Casing Gear Hub

Gear Hub