Advantages and Applications of Aluminum Forging in Automotive Components #

Aluminum forging has become a cornerstone in the automotive industry, enabling the production of a wide array of critical vehicle parts. This process is especially valued for its ability to deliver components that are both lightweight and exceptionally strong, making it a preferred choice for modern automotive engineering.

Key Benefits of Aluminum Forged Automotive Parts #

- High Strength-to-Weight Ratio: Aluminum’s inherent properties allow for the creation of parts that are significantly lighter than their steel counterparts, without compromising on strength. This directly contributes to improved fuel efficiency and enhanced vehicle performance.

- Enhanced Mechanical Properties: The forging process refines the grain structure of aluminum, resulting in components that are more resistant to stress, strain, and fatigue. This leads to longer-lasting and more reliable automotive parts.

- Corrosion Resistance: Aluminum forgings offer excellent resistance to corrosion, making them ideal for use in the demanding environments encountered by vehicles.

- Complex Geometries: Forging enables the production of intricate shapes and designs that are difficult or impossible to achieve through other metal forming methods. This flexibility supports the development of high-performance and specialized automotive components.

- Environmental Impact: The use of lightweight aluminum forgings helps reduce vehicle weight, which in turn lowers energy consumption and emissions, supporting sustainability goals in the automotive sector.

Custom Forging Services for Automotive Applications #

Al Forge Tech stands out among automotive forging companies by offering tailored solutions for aluminum automotive components. Utilizing advanced methods such as cold forging and hot forging, the company is equipped to meet diverse customer requirements, from standard parts to highly customized designs. For inquiries or further information, customers are encouraged to contact Al Forge Tech.

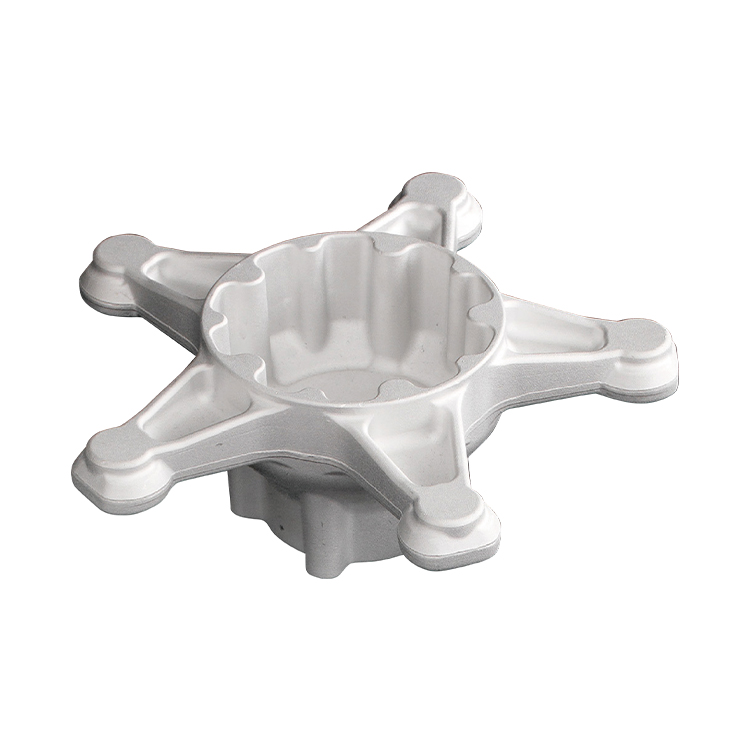

Product Gallery: Aluminum Forged Automobile Parts #

Al Forge Tech continues to support the automotive industry with high-quality, precision-forged aluminum parts, ensuring vehicles benefit from the latest advancements in material science and manufacturing technology.

Hub

Hub Brake Caliper

Brake Caliper Control Arm

Control Arm Control Arm

Control Arm Control Arm

Control Arm Piston

Piston